Purchase Subcontract

Key Features

Provision to send product(s) with Bill of Materials to subcontracting vendor for processing.

Provision to get the processed product(s) through Purchase order.

Track used / processed quantities at subcontracting vendor’s location

Works with Multi Company architecture

Negative Stock is controlled in all the Transactions

The WorkFlow

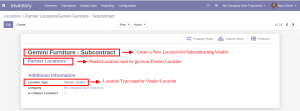

Step 1 : Go to ‘Location’ Master Under configuration menu in Inventory module.

Create a new Location for subcontracting vendors respectively with the following parameters

Location Name = Subcontract Location

Parent Location = Partner Location

Location Type = Vendor Location

Note: Subcontract location has to be created per Vendor & company

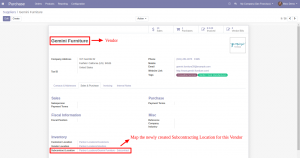

Step 2 : Create a new Vendor (if not already available) & map the newly created subcontracting location (per vendor) in the new field ‘Subcontract Location’ respectively.

Note: Repeat this step for all subcontracting vendor(s)

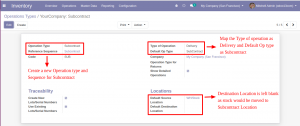

Step 3 : Create a new Operation type respectively with the following parameters

Operation Types Name = Subcontract Location

Reference Sequence = Partner Location

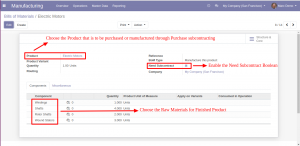

Step 4 : Go to ‘Bill of Material’ Master under ‘Master data’ menu in ‘Manufacturing’ module

Create a new ‘Bill of Materials’ with the below parameter to be set

Need Subcontract = Select the boolean

The WorkFlow

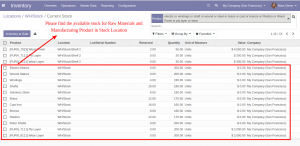

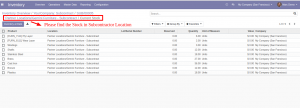

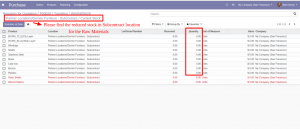

Step 1 : Please find the available Stock in Stock Location for all the Bill of Materials and Product that is to be Purchased or Manufactured through Purchase Subcontracting.

Step 2 : Please find the Available Stock in Subcontract Location.

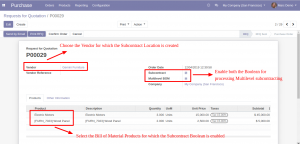

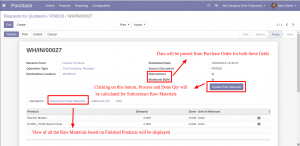

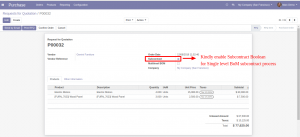

Step 3 : Create a Purchase Order –> enable the Subcontract Boolean and Multilevel BoM for the Finished Product with the respective Subcontractor Partner (vendor) with Multilevel BoM.

Step 4 : Confirm the Purchase Order to create the Receipts which displays both Finished Product and its respective Bill of Materials (Raw Materials for Subcontractor) for Multilevel BoM.

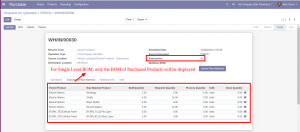

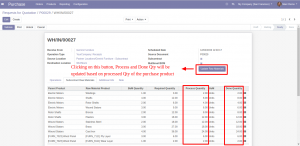

Step 5 : Please find the Subcontract Raw Materials View in Purchase Order Receipts.

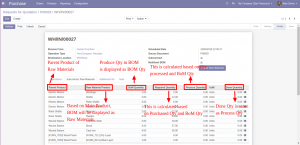

Raw Material Product = This Field displays the Products that is created as the Bill of Materials for the Purchased Product.

Parent Product = This Field displays BoM Product of the Raw Material Product.

BoM Quantity = This Field displays the Produce Quantity of the Bill of Materials based on the Purchased Product.

Required Quantity = Required Quantity is calculated based on the purchase quantity of the purchased product and BoM Quantity.

Process Quantity = Process Quantity is calculated based on the quantity that is to be processed in Receipts and BoM Quantity. Also it will updated by clicking on the “Update Raw Materials” button in Receipts Form.

UoM = It is nothing but the Products Unit of Measure

Done Quantity = Done Quantity is same as Process Quantity

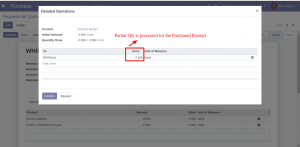

Step 6 : Process the Quantity of the Purchased Product partially in order to check the Backorder Flow and the stock updation of Subcontracted Raw Materials.

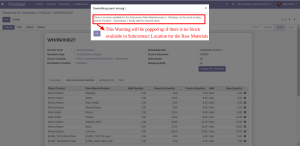

Step 7 : Validation Error while processing the Incoming Shipments

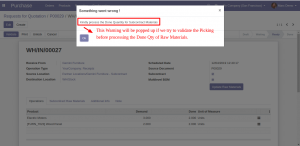

Step 8 : ‘Process Quantity’ and ‘Done Quantity’ are updated based on the processed quantity and BoM quantity by clicking on the “Update Raw Materials” button.

Step 9 : Lot / Serial Number for the Products has to be updated manually

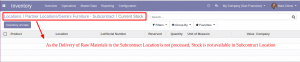

If the Stock is not available in Subcontract Location for respective Subcontracted Raw Materials, the below Warning would pop up while validating the receipts

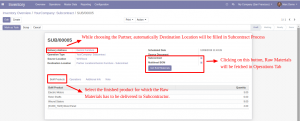

Step 10 : In order to deliver the Raw Materials to Subcontract Location, choose the Vendor where Subcontract location will be set as default Destination Location automatically.

BoM Products for respective finished/subcontracted parent product will be present next to ‘Operations’ tab where you will have to choose the Bill of Material Product and update the Quantity that is to be delivered.

Clicking on the “Update” button, the Bill of Materials for the Selected Product and their Quantities will be displayed in Operations Tab.

We can also process the delivery of Raw Materials through Delivery Orders by enabling the ‘Subcontract’ Boolean and clicking the ‘Update’ button.

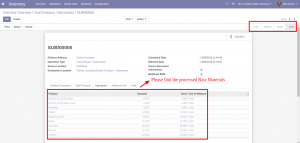

Step 11 : Once after the updation of Raw Materials, choose the Lot / Serial numbers for the Products and Validate the same to move the Stock to Subcontract Location from Stock Location.

Step 12 : Please find the Current Available Stock in Subcontract Location.

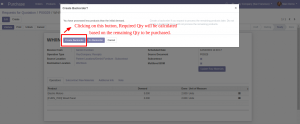

Step 13 : ‘Required Quantity’ will be calculated on remaining purchase quantity and BoM quantity in ‘Subcontract Raw Materials’ tab.

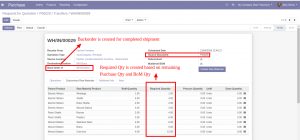

Step 14 : Backorder is created for the Completed Purchase Receipts and Required Quantities are updated.

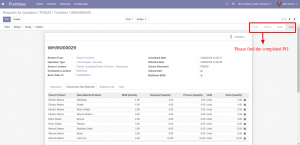

Step 15 : Please find the completed Incoming Shipments.

Step 16 : Find the Reduced Stock in Subcontract Location for the Bill of Materials.

Step 17 : Find the Available Stock for the Purchased / Subcontracted Product in Stock Location after successful receipt.

Step 18 : Create a Purchase Order –> enable the Subcontract Boolean and Multilevel BoM for the Finished Product with the respective Subcontractor Partner (vendor) with Singlelevel BoM.

Step 19 : Confirm the Purchase Order to create the Receipts which displays both Finished Product and its respective Bill of Materials (Raw Materials for Subcontractor) for Multilevel BoM.